When it comes to clutch performance, most drivers focus on the disc, pressure plate, or flywheel. But there’s another component doing critical work behind the scenes: the clutch slave cylinder. This small hydraulic part plays a huge role in how your clutch engages—and when it starts to fail, you’ll feel it every time you shift.

Whether you’re driving a muscle car, a pickup, or a compact truck, maintaining a healthy slave cylinder is key to smooth operation. Let’s break down why this component matters and how it impacts clutch performance, shift quality, and overall drivability.

Impacts on Smooth Shifting

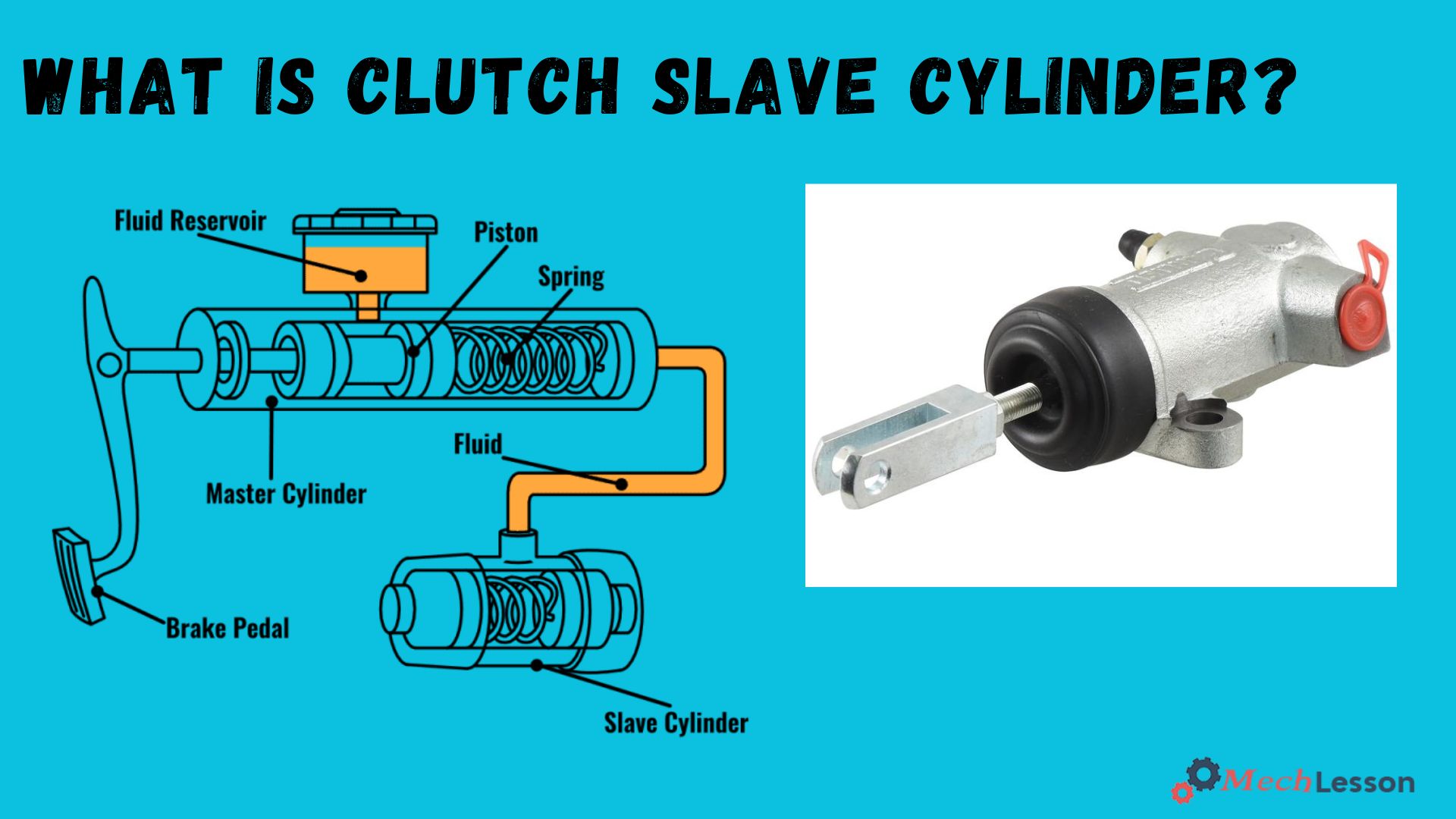

The slave cylinder is part of your clutch’s hydraulic system. When you press the clutch pedal, the master cylinder sends fluid through the lines to the slave cylinder. That hydraulic pressure causes the slave cylinder to extend, disengaging the clutch so you can shift gears. Without consistent pressure and movement, your clutch won’t work properly.

In high-performance cars like the 2006 Pontiac GTO Clutch Slave Cylinder, even the slightest delay in clutch release can affect launch control, throttle response, and overall shifting accuracy. If the slave cylinder is worn or leaking, it can cause the clutch to engage too slowly or inconsistently—resulting in missed shifts, grinding gears, or a stalling engine.

A healthy slave cylinder keeps pedal feel consistent and shift timing precise. It also reduces wear on your clutch disc and transmission by allowing smooth, complete disengagement of the drivetrain. Drivers who push their cars hard—or regularly tow heavy loads—will benefit the most from a well-maintained hydraulic system.

Clutch Response Time

One of the most noticeable effects of a failing slave cylinder is poor clutch response time. If there’s a delay between pressing the pedal and the clutch disengaging, you might experience difficulty getting into gear, jerky starts, or rolling at stoplights.

In work trucks like the 2007 Ford F150 Clutch Slave Cylinder, delayed clutch response can make towing and hauling more difficult. Under load, poor hydraulic pressure can even lead to clutch slippage or premature component failure. Replacing the slave cylinder ensures the clutch engages quickly and fully—exactly when you need it to.

You might also notice issues such as:

- A soft or sinking clutch pedal

- Grinding when shifting into reverse

- Gear slip when under throttle

- Clutch pedal not returning properly

These are all indicators that your slave cylinder is failing to build or hold the necessary hydraulic pressure.

In compact trucks like the 2001 Chevrolet S10 Clutch Slave Cylinder, these symptoms can be especially pronounced, since older models often operate with aging components and outdated hydraulic systems. A replacement slave cylinder is a low-cost upgrade that dramatically improves shifting comfort and drivability.

Additional Benefits of a New Slave Cylinder:

- Improved fluid retention and leak resistance

- Smoother pedal feel and engagement point

- Reduced clutch chatter and pedal vibration

- Better compatibility with performance clutches

Replacing the slave cylinder during a clutch job—or at the first sign of failure—can also prevent premature wear on new clutch components. It’s a small part that protects a much more expensive system.

Your clutch system is only as strong as its weakest component, and the slave cylinder is often one of the first to wear out. By maintaining or replacing this part proactively, you improve everything from shift quality to overall driving comfort.

Whether you’re restoring an older S10, towing with an F150, or carving corners in a GTO, a fresh clutch slave cylinder keeps your pedal feel crisp, your engagement smooth, and your transmission protected.