CNC milling and CNC turning are some of the most utilized processes in fabrication for part production. Each process has its benefits, and knowing how to utilize them can make a big difference in production efficiency. Let’s review the differences of each technique, outline their advantages, and define which is better for your components.

For B2B Companies looking for precise machining parts, collaborating with reliable CNC machining suppliers China guarantees that quality is delivered and the appropriate manufacturing process that achieves economical production targets is applied.

What is CNC Milling?

CNC milling relies on a machining process that utilizes rotating cutters to slice away material from a workpiece. It is well-suited for the fabrication of complicated geometrical shapes and components of different sizes and does so with high accuracy. Parts that need flat features, drilled holes, pockets, and detailed surfaces fabricated are ideally done using CNC milling. The component can move in multiple directions simultaneously which allows the creation of intricate shapes. Furthermore, CNC milling provides a great deal of flexibility in rapid design changes and custom modifications.

The detailing capabilities of CNC milling machines is one of their most significant advantages. The ability to produce components with highly intricate, angled and undulating surfaces allows for an enhanced level of detail. In fact, CNC milling is a great option for a variety of industries like automotive, aerospace, medical devices milling due to its versatility in materials which include metals, plastics, and composites. Parts produced using CNC milling get high surface quality and are the preferred method of complicated features with precise measurements.

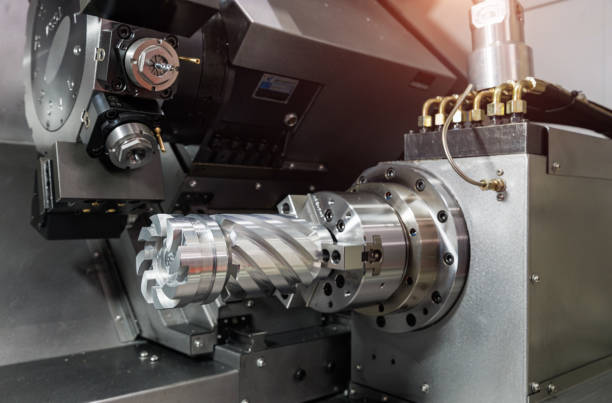

What is CNC Turning?

CNC milling relies on a machining process that utilizes rotating cutters to slice away material from a workpiece. It is well-suited for the fabrication of complicated geometrical shapes and components of different sizes and does so with high accuracy. Parts that need flat features, drilled holes, pockets, and detailed surfaces fabricated are ideally done using CNC milling. The component can move in multiple directions simultaneously which allows the creation of intricate shapes. Furthermore, CNC milling provides a great deal of flexibility in rapid design changes and custom modifications.

The detailing capabilities of CNC milling machines is one of their most significant advantages. The ability to produce components with highly intricate, angled and undulating surfaces allows for an enhanced level of detail. In fact, CNC milling is a great option for a variety of industries like automotive, aerospace, medical devices milling due to its versatility in materials which include metals, plastics, and composites. Parts produced using CNC milling get high surface quality and are the preferred method of complicated features with precise measurements.

Key Differences Between CNC Milling and CNC Turning

Recognizing variances in CNC milling and CNC turning will best assist you in choosing which part requirements CNC process is most beneficial to you.

- Movement of the Workpiece: In CNC milling, the stationary or action moving workpiece can be in multiple axes while the tool moves or rotates with the workpiece. In CNC turning, the rotating workpiece as a cutting tool is the opposite of the approach taken in milling. The difference here is that while the workpiece in turning has more of a swirling motion, the milling action can be multilateral. Because of this, CNC turning is ideal for rotationally symmetrical components whereas CNC milling is better for multi-dimensional and non-rotational features.

- Use Cases: When dealing with parts that require pockets, surfaces, as well as shapes with defined details features, CNC milling is usually the most aggressive option. Rotating parts that are cylindrical in shape such as tubes, shafts, or rings are best suited for CNC turning. These different orders of complexity add ideal functionality to each procedure, allowing the CNC milling process to achieve complex geometries as opposed to the more straightforward forms produced by the CNC turning process.

- Enhancing Efficiency: Working with CNC milling companies, material can be removed from almost any area. Simpler, more efficient, and repetitive cuts along the spinning workpiece’s axis is the most logical CNC turning method. The choice between the two methods can be completely predetermined based on the shapes of the parts being created. As expected, parts with complex designs will be produced with the use of CNC milling, while greater precision and speed will come from the use of CNC turning for cylindrical parts.

Recognizing these differences will allow firms to select the appropriate procedure based on feature shape, acceptable tolerances, and quantity of parts needed.

When to Choose CNC Milling or CNC Turning

When deciding between CNC milling and CNC turning, businesses should consider the complexity and design requirements of the part.

- Use CNC Milling for:

Parts with intricate shapes, multi-sided features, or precise surface finishes. Milling is ideal for parts that require detailed geometry such as pockets, grooves, or specific surface textures.

Components requiring detailed pockets, grooves, or threading. CNC milling can easily handle these tasks with high precision and accuracy.

Complex geometries that need to be machined from multiple angles. The ability to operate on multiple axes means milling machines can handle a diverse range of parts.

- Use CNC Turning for:

Cylindrical or rotational parts such as shafts, pins, and rings. CNC turning excels at creating perfectly round components with high symmetry and minimal tolerances.

High-speed production of parts with simple geometries and high-volume requirements. CNC turning is highly efficient, especially for mass production runs of parts with similar designs.

Parts that require high precision in terms of concentricity and roundness. CNC turning ensures that parts meet tight tolerances, which is critical for components that need to fit seamlessly with other moving parts.

Working with experienced CNC machining suppliers China can help you make the right decision, ensuring your parts are produced efficiently and to the highest standards.

Conclusion

To summarize, CNC turning and CNC milling both have their respective perks based on the part’s design and intended use. The best option for complex shapes and features is working with CNC milling companies. On the other hand, CNC turning is superior in manufacturing precise and symmetrical parts in large quantities of time-sensitive work.

Working with reliable CNC machining suppliers China helps B2B companies select the appropriate machining method for their components which enhances production efficiency, decreases expenses, and ensures quality. You will be able to provide end-users and various industries with high-performance components by choosing the correct method.